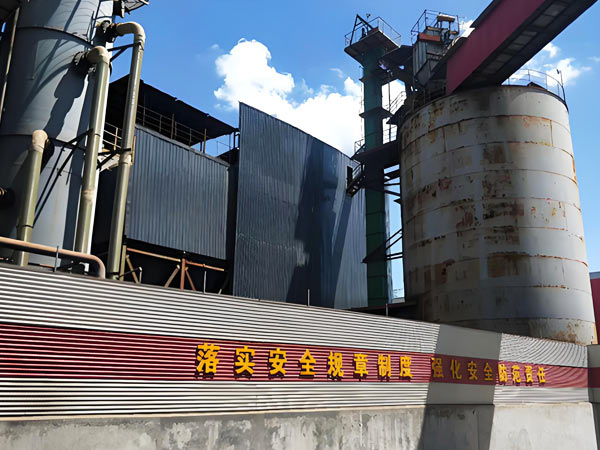

Intelligent Precision SNCR Ammonia Injection Denitrification

Bolaida SNCR Denitrification leverages artificial intelligence and precision control to reduce nitrogen oxide (NOx) emissions, converting them into nitrogen (N₂) and water (H₂O). This improves air quality and supports ultra-low emissions and green production in process industries!

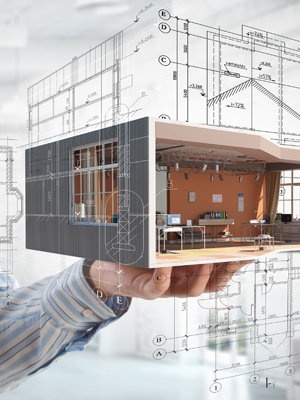

This intelligent precision denitrification system consists of an ammonia water injection system, including:

Ammonia distribution system (downstream of ammonia pumps),

Injection lance system,

Smart advanced control system.

Core software: Optimization control, prediction algorithms, and ammonia distribution models.

System Value

Energy Saving

Reduces ammonia consumption by 20%-60%.

Consumption Reduction

Minimizes ammonia slip and equipment corrosion.

Emission Reduction

Ensures NOx compliance.

Environmental Compliance

Helps cement plants achieve Class A ultra-low emission standards.

Technical Principle

The system connects to the PLC of the distribution device and the customer’s existing DCS via communication protocols. Using machine learning and data-driven analysis of the kiln system, it simulates how process conditions affect SNCR lance efficiency. It tracks operations in real-time, precisely determines ammonia dosage, and selects optimal injection points to ensure evaporation and reaction occur in high-NOx zones. This minimizes ammonia slip (maximizing ammonia utilization) and achieves high NOx removal rates, reducing NOx emissions, controlling ammonia slip, saving ammonia consumption, and maintaining peak efficiency.

Advantages

01

Machine learning optimizes injection at highest-efficiency points. Real-time NOx emission prediction enables feedforward control.

02

Optimized lance layout with independent control per group. Real-time adjustment of ammonia/compressed air flow ensures optimal droplet size.

03

Real-time hourly/daily NOx averaging for precision control. Self-adaptive and self-learning models adjust to operational changes.

04

Advanced process control + real-time optimization achieves ≥90% NOx removal for ultra-low emissions.

05

Accepts ammonia slip monitoring data for feedforward control. Distribution valves use globally top-tier imported components.

System Features

Proprietary AI System

Analyzes kiln conditions in real-time to identify optimal injection points.

Predicts NOx emissions for the next 3 minutes.

Calculates ideal ammonia dosage.

High Stability

Hardware: Premium imported components ensure precision control and long-term reliability.

Software: Emission prediction and kiln condition tracking via big data analytics enable refined control for stable compliance.

≥90% NOx Removal Efficiency

Reaches up to 93% in optimized production lines, surpassing conventional technologies.

Strong Compatibility

Synergizes with staged combustion, duct denitrification, SCR, etc., without affecting production.

Cost-Effectiveness (NOx≤50mg)

Low investment cost with rapid ROI.

Reduces ammonia usage by 20%-60%, slashing operational expenses.

Bolaida SNCR VS Conventional SNCR